Chemical composition: polyoxyethylene, polyoxyepretene block polymer

Class type: not separated

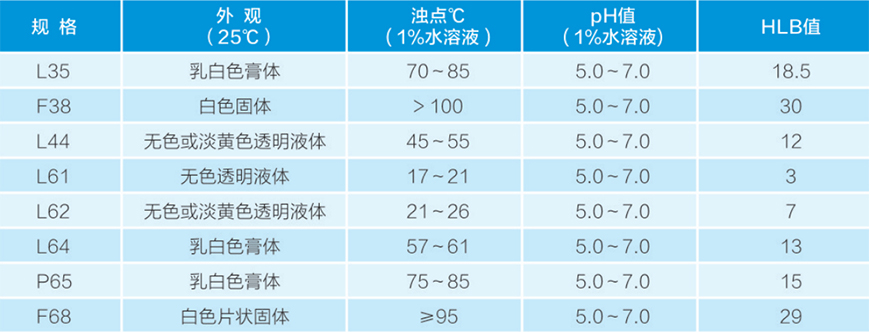

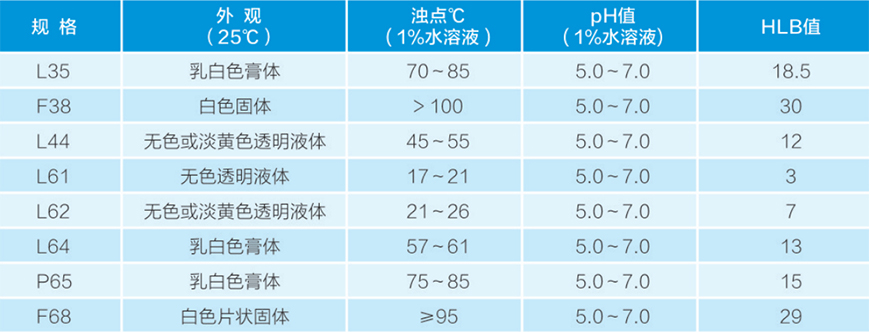

Technical index ///---------------------------------

Performance and characteristics ///---------------------------------

1, as a low foam detergent or defoamer. L61, L64, F68 are used to prepare low foam, high detergents synthetic, L61 is used as a defoamer in the paper or fermentation industry.

2, polyether is very low toxicity, commonly used as a drug excipient and emulsifier, in the mouth, nose spray, eye, ear drops and shampoo are often used.

3, polyether is an effective wetting agent, can be used for fabric dyeing, camera development and electroplating acid bath, F68 in the sugar factory, due to the increased permeability of water, more sugar can be obtained.

4, polyether is an effective antistatic agent, L44 can provide lasting electrostatic protection for synthetic fibers.

5. Polyether is used as dispersant in emulsion coating. F68 is used as emulsifier in the polymerization of vinyl acetate emulsion. L62, L64 can be used as pesticide emulsifier, as coolant and lubricant in metal cutting and grinding. Used as a lubricant when rubber is vulcanized.

6, polyether can be used as crude oil demulsifier, L64, F68 can effectively prevent the formation of hard scale in the oil pipeline, and for the recovery of secondary oil.

7, polyether can be used as a papermaking assistant, F68 can effectively improve the quality of coated paper.

8, F38 can be used as emulsifier, wetting agent, defoamer, demulsifier, dispersant, antistatic agent, dust removal agent, viscosity regulator, foam control agent, dye levelling agent gelling agent, etc., used in the production of agricultural chemicals, cosmetics, pharmaceuticals; It is also used for metal processing cleaning, pulp and paper industry, textile processing (textile, finishing, dyeing, soft finishing), water quality treatment, and also used as bleaching aid.

9, P65 is mainly used in the wool spinning industry, as a wool protective agent, adding about 0.3% in the wool carbonization process, can reduce the wool scale damage and enhance the strength of single fiber 10%. Reduce spinning break rate by 10%.

Packing and storage ///---------------------------------

200kg drum packaging, 50kg plastic drum packaging. Store and transport as general chemicals. Store in a dry and ventilated place.

Shelf life ///---------------------------------

Two years.